- Sanseidou

- Food Processing Equipment

- Cooking Equipment

- Store Advertising Equipment

- Refrigeration Equipment

- Commercial Furniture

- Kitchenware

- Tableware

Santetsu Engineering-H1000A1-Electrostatic Defrosting Preservation Machine(with Depak)

Code : H1000A1

External Dimensions(mm):W1400xD825xH1980

Internal Dimensions(mm):W1280xD673xH1380

Main Material of the Cabinet:304 Stainless Steel

Depth when the Door is Opened(mm):1475

Volume(Liters):1100

Number of Doors:4

304 Stainless Steel Shelves:10

Net Weight(kg):200

Power Supply:220V~50Hz 1PH

Running Input Current(A):4.5

Power(W):600

Refrigerant:R134a

Refrigeration Method:Air-cooled

Temperature Control Range:-6℃ ~ +35℃

Thawing Modes:

1. Set the specified core temperature thawing mode.

2. Set the thawing time thawing mode.

Others:It will automatically switch to the preservation mode after the thawing reaches the set value.

Advantages

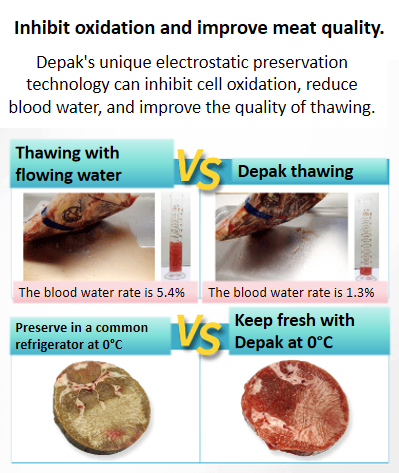

Our proprietary “DEPAK” technology enables freezing, thawing, and storage of food without compromising its freshness.

By suppressing cell destruction and reducing drip loss, it not only preserves flavor, but also contributes to increased work efficiency, reduced labor costs and improved sanitary conditions.

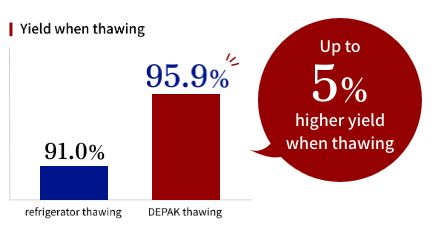

Improve Yield and Quality of Food Ingredients

Improve Yield and Quality of Food Ingredients

Our proprietary “DEPAK” technology thaws each cell evenly, preventing cell tissue breakdown and minimizing the amount of drip loss during thawing. Food can be thawed while maintaining its freshness for a long period of time, and an improvement in yield during thawing can be expected. By reducing food loss, we contribute not only to delicious food but also to improved business management.

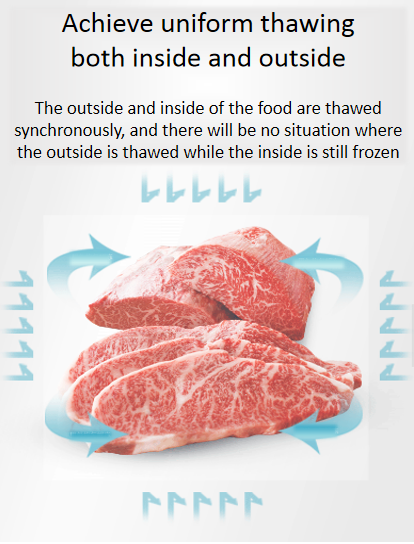

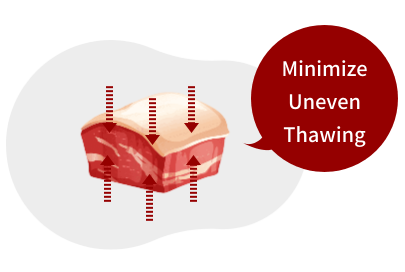

Uniform Thawing for Greater Efficiency

Uniform Thawing for Greater Efficiency

With conventional thawing methods, thawing is done by gradual heating, which inevitably results in uneven thawing. Uneven thawing leads to the expansion of water in the cells, resulting in damage. We have done extensive research in the pursuit of efficient heat exchange. By controlling the temperature and airflow with DEPAK, differences between the center temperature and surface temperature of the food are minimized, enabling even thawing all the way to the core.

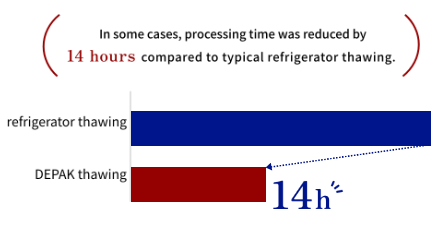

Shorten Thawing Time

Shorten Thawing Time

DEPAK thawing promotes thawing with calculated temperature and airflow while reducing the temperature difference between the surface and center of the frozen food, thereby greatly shorten thawing time without loss of flavor.In addition, it automatically switches to freshness preservation mode after thawing is complete, so there is no need to transfer the food from the thawing machine to a refrigerator. It contributes to a reduction in not only thawing time, but also labor costs.